Chicago Industrial Reuse and Parts Blog-Newsgroup > Downtown

> New

> Industrial

> Restaurant

> Baileigh rdb-050 tube bender pipe bending tubing rmd

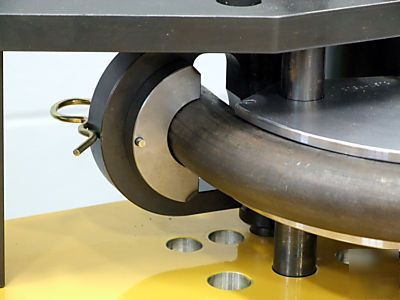

Baileigh rdb-050 tube bender pipe bending tubing rmd

The RDB-050 tube bender makes the other benders out there look like toys. There are many advantages to the RDB-50 over other manual benders on the market.

* 3 bending speeds (4,8 or 12 degrees per pull)

* Massive 1" thick drive arms

* Aluminum bronze bushings at all pivot points

* Fast and easy hook arm inserts for different size tube

* Replaceable aluminum bronze counter bend die insert

* Affordable die sets are available in 90 or 180 degrees

* Some of the best bend quality on the market

http:// /videos-pages/rdb-050-video.php

http:// /videos-pages/tubing-bender-050-2inch-video.php

http:// /videos-pages/tubing-bender-050-2-half-inch-video.php

Baileigh Industrial s newest bender, the RDB-050, was designed from the ground up to deliver world class bend quality in an affordable package. This unit is aimed squarely at the serious home fabricator who may not be able to justify a larger hydraulic or programmable bender but still wants the quality and performance Baileigh Industrial is famous for.

This revolutionary new design incorporates features previously seen only on much more expensive benders. Heavy duty bushings incorporated at all wear points for incredible service life and increased bend capacity. This is a bender for life!

Three speed operation makes quick work of any bending job. Simply change pin location to adjust the amount of movement per pull (4, 8, or 12 deg.) no confusing or time wasting disassembly required. For very light weight materials the operator can bend in one smooth pull all the way to 200 deg. This new leverage action along with an incredibly rigid framework allows for huge bend capacity up to 2 1/2 OD (.120 wall) Mild Steel or 2 OD (.120 wall) Chromolly Tubing.

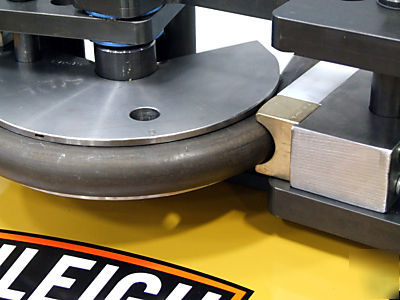

A simple anti-spring back mechanism assures precise bend control and increased operator safety. At no time does the operator have to hold the arm in place and be subjected to dangerous backlash, an important consideration when bending the likes of Chromolly. Tooling changeover is fast and easy as no disassembly of the machine is necessary. Simply pull a few pins and slide in the new tooling it s that easy! The whole process can be accomplished in a matter of seconds.

Once the part is completed simply slide the finished piece out of the machine. Our innovative design eliminates the need to disassemble the unit or remove tooling to release your work piece making the bend process clean and simple. Round tube tooling is available for either 90 or 180 degree bends and incorporates the same replaceable aluminum/bronze counter die inserts that Baileigh Industrial is famous for. Hook arm inserts for varying tube sizes assist with fast tooling changes. True to form, our tooling remains the best in the industry.

http:// /pdf/050/050list.pdf

If you have any questions, need technical assistance, or would like to place an order please reply to this message or give me a call.